Quality Policy

Provide You The High Quality Products, That Meets Your Expectation.

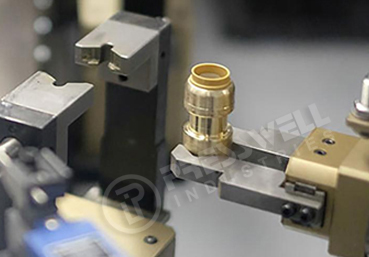

Each component produced at Presswell Industries follows stringent quality procedures and vigorous quality checking at all stages of manufacturing cycle to ensure that near zero defect components are supplied to our valued customers.

To support our near zero defect component manufacturing philosophy, we train all our staff on regular basis to keep them up to date regarding latest instruments and latest trend in quality.

We keep on updating and upgrading our instruments as per customer and component requirements, so as to assure supply of best quality products to our customers.

We keep on updating and upgrading our instruments as per customer and component requirements, so as to assure supply of best quality products to our customers.

Instruments

Quality Testing Equipments

We adhere to strict Quality Control Measures. Vigorous tests are conducted on all incoming raw material, intermediate and finished products to ensure best quality products as per Quality Assurance Plan. A team of trained supervisors and quality control inspectors ensures that the quality is maintained at all the stages of production.

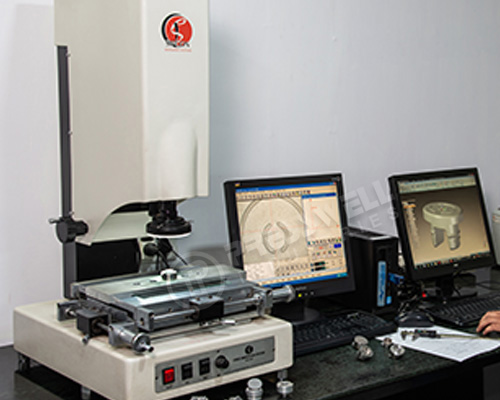

Vision Measuring System

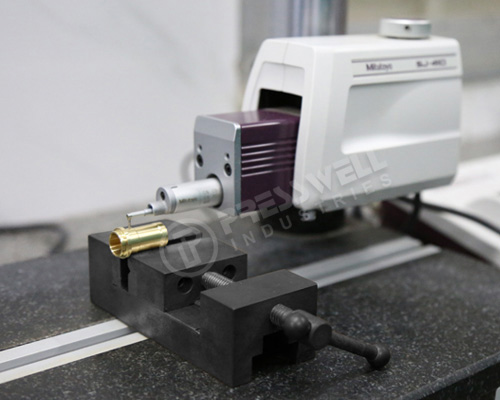

Roughness Tester

Digital Height Gauge

Hardness Tester

Digital Micrometer

Thread Ring & Plug Gauges

Quality Assurance

Receiving inspection of purchased products

-

Chemical and Physical testing of each Raw Material as per control plan with reference to Raw Material Standard of purchased bright bars, forgings, castings & other assembly spares.

-

Dimensional inspection of purchased bright bars, forgings, castings and other assembly spares.

In-process Inspection

-

Set up approval of manufacturing process as per defined control plan with reference to drawing prepared.

-

In-process inspection as per defined control plan with reference to drawings prepared on hourly basis.

-

Separate identification and traceability of non-conforming products at In-process stage.

Final Inspection

-

100% Visual inspection of each lots produced as per defined plan with reference to visual defects like operation missing, rusts, blow holes, rough finishing, dent marks, tool marks and input material defects.

-

Sampling dimensional inspection of all critical dimensions as per defined control plan with reference to drawing prepared.

-

100% dimensional inspection of major critical dimensions of small tolerances as per defined control plan with reference to drawing prepared.

-

Separate identification and traceability of non-conforming products as final stage.

Pre-Dispatch Inspection

-

Pre-dispatch inspection before deliver the products to customer as per their requirements along with inspection report and separate identification of inspected samples with reference to customer or internal drawing.